The Computer

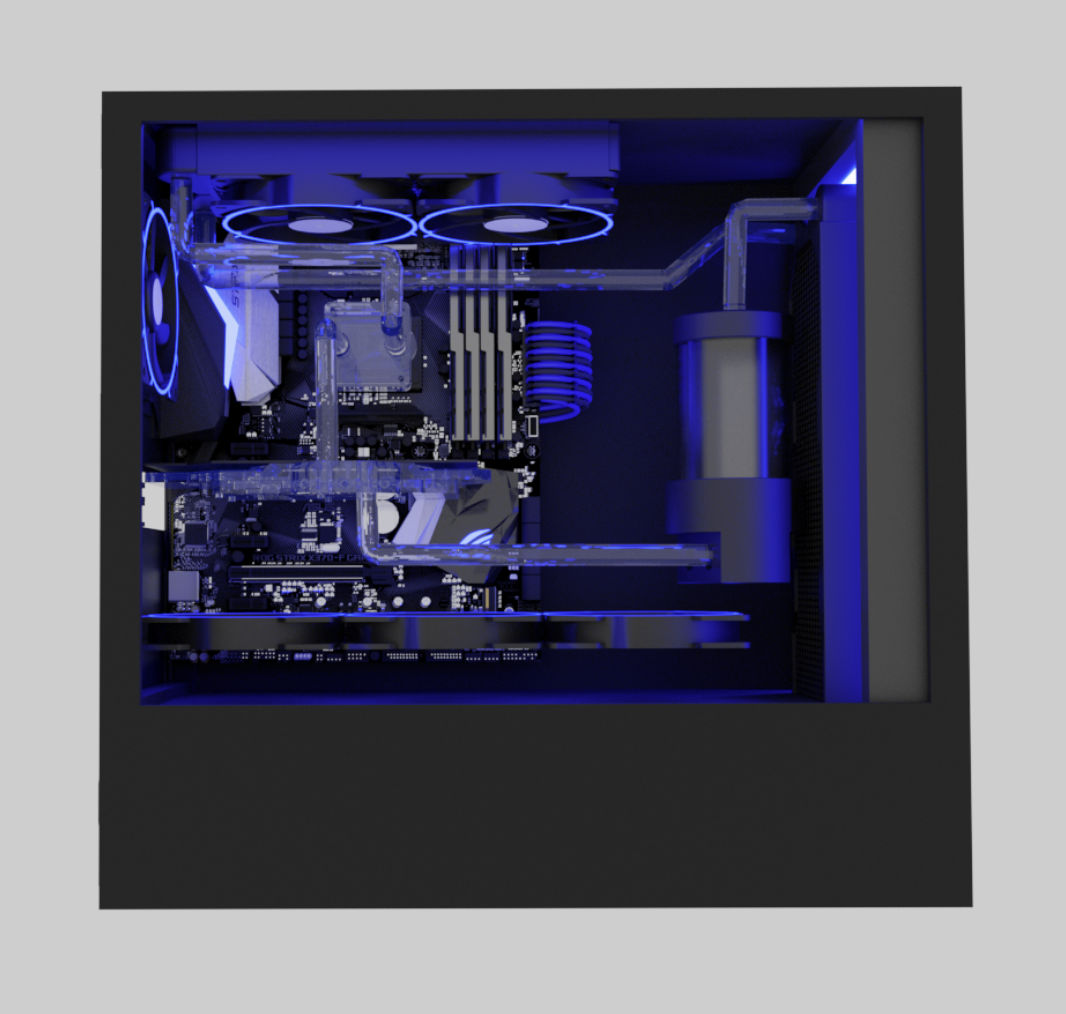

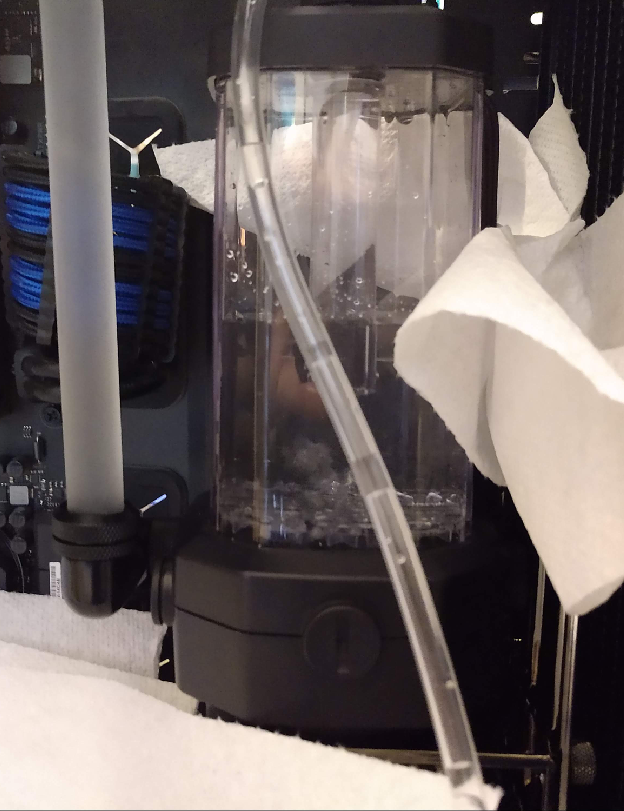

Building a custom water-cooled PC involves meticulous planning and execution for both performance and aesthetics. It starts with selecting quality components and designing a custom loop using software like Blender for visualization. PMMA plastic tubing, known for its strength and ease of bending, routes the coolant, while efficient cable management ensures optimal airflow. Problem-solving skills are essential for tubing and cable routing. The result is a high-performance PC with superior cooling, demonstrating technical expertise and attention to detail.

Skills

Hardline

Plan

- Building Hardware

Gained extensive experience in assembling and configuring computer hardware, enhancing technical skills and attention to detail. - Cable Mangement

Demonstrated strong planning and organizational skills through thorough research and project strategizing. - Planning

Demonstrated strong planning and organizational skills - Problem Solving

Engaged in complex problem-solving to determine effective cable routing and system optimization.

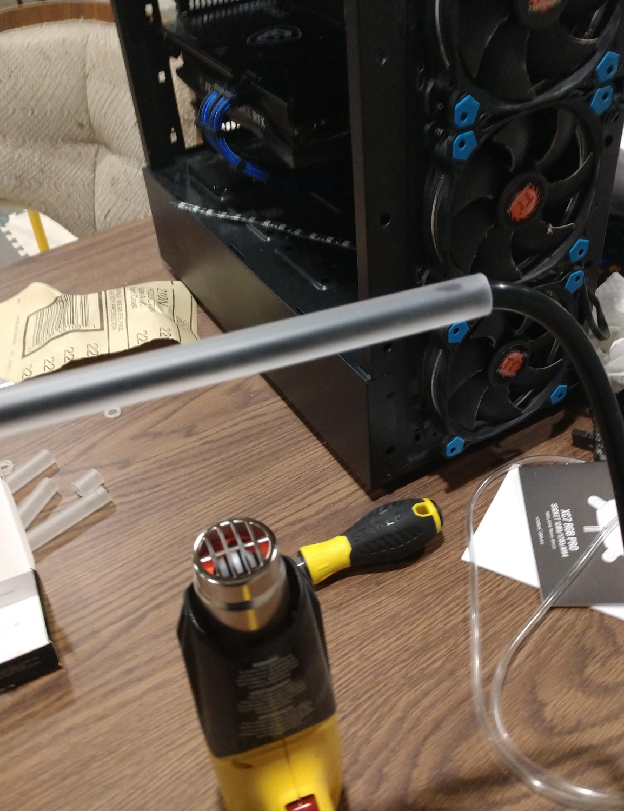

PMMA Plastic

- Cheap

Strong and cost-effective compared to other plastics. - Safe

Certified as food-safe plastic. - Reusable

Fully recyclable. - Strong

Withstands significant pressure without cracking. - Melting

Melts at 320°F, easily bent with a heat gun.

- Design

Used Blender to model and plan custom hardware setups. - Part Picking

Researched and selected high-quality, cost-effective components.

Copyright © Erik Sorensen 2024